Contact us to learn more about our products!

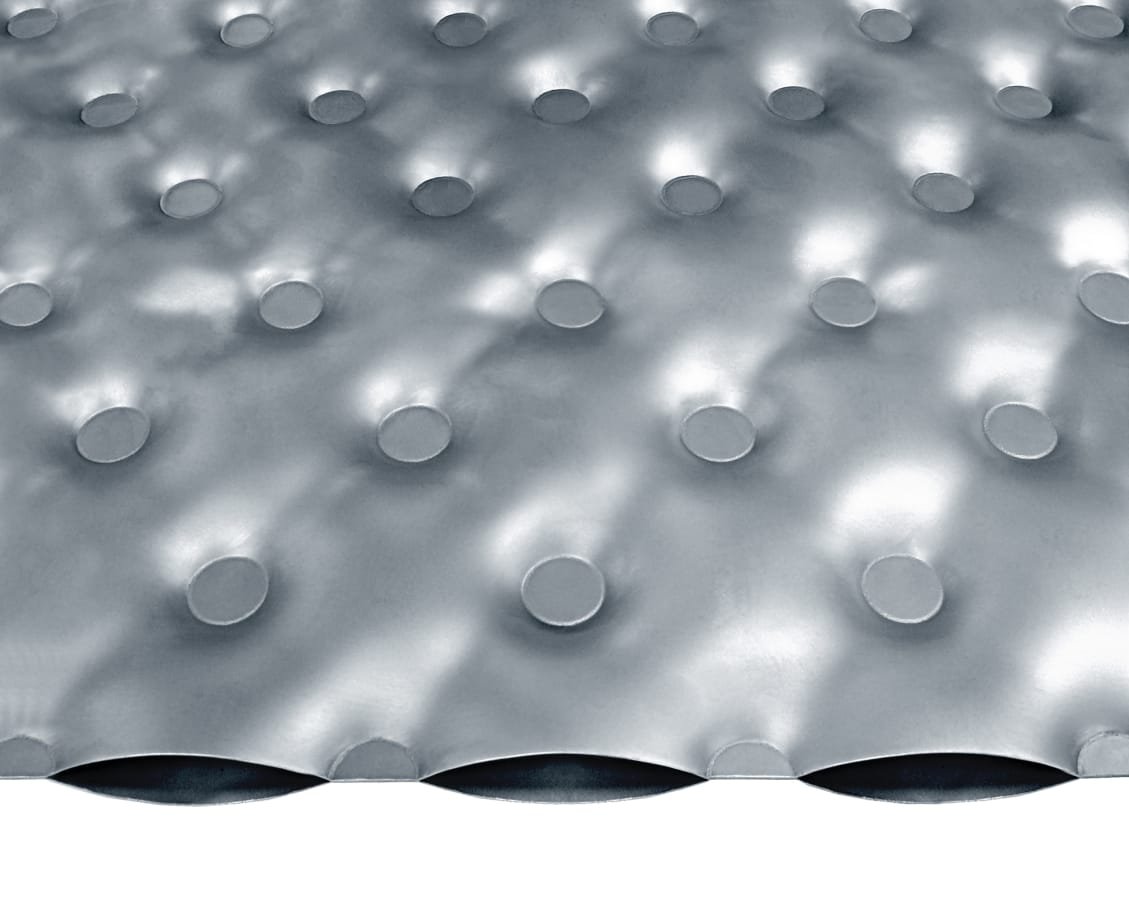

Flanged and dished heads with Omega Laser Plate

Omega Thermo Products is one of the few suppliers that can also supply F&D heads with Laser Plates under ASME, CE-PED, and CRN. Many of the bottoms supplied by Omega are used in the chemical and pharmaceutical industry. Also F&D heads are used for process tanks, with a full vacuum or high pressure prevailing in the tank. Design

Two flat sheets of stainless steel are welded together and after this process the flat head is sent out for forming. Generally the Laser Plate covers 80% of the heads surface to allow the head to be formed without forming on the laser welded portion. The forming is hydro formed or bump formed depending on the size. The heads are sent to the customer fully formed, trimmed and ready to be installed on the tank. Once the head is installed the jacketing will be inflated hydrostatically.Advantages

Using a laser welded head is a cost savings over welding on pre-formed dimple. There is also flexibility in design for isolations of tank connections and openings.Other tank bottoms

Beside Flanged and Dished heads we can also provide cones or reverse dished heads with Laser Plates.If you have special requirements, please contact us.

DESIGN FREEDOM

UNIFORM HEATING / COOLING

CAN BE DESIGNED TO ASME

Read more about our Heat Exchangers & Applications in our literature!

SPECIFICATIONS

Material

We can process the following stainless steel materials:Austenitic material (304, 304L, 316, 316L, 317, 321)(Super) duplex materials (2205, 2507, 2304, LDX-2101)Nickel alloys (Nickel, Hastelloy, Inconel)

If you have a F&D head of a different material, please contact one of our engineers.Thicknesses

Inflated thickness on smooth thickness:20ga on 12ga18ga on 10ga16ga or 18ga on 7ga(3/16")16ga or 18ga or 14ga on 1/4"16ga or 18ga or 14ga on 5/16"

Pressure and temperature

Our Laser Plates can handle a working pressure of > 1500 psi, depending on the chosen temperature. F&D dishes can be used for an operating pressure up to approx. 725 psi.F&D heads that are covered with Laser Plates allow you to reach temperatures of 570 °F, depending on the choice of materials.Certificates

Omega Thermo Products produces F&D heads under the following certification:ASME U-StampCE-PEDCRN

Contact us to learn about different product variations, materials & heat transfer mediums!