Contact us to learn more about our products!

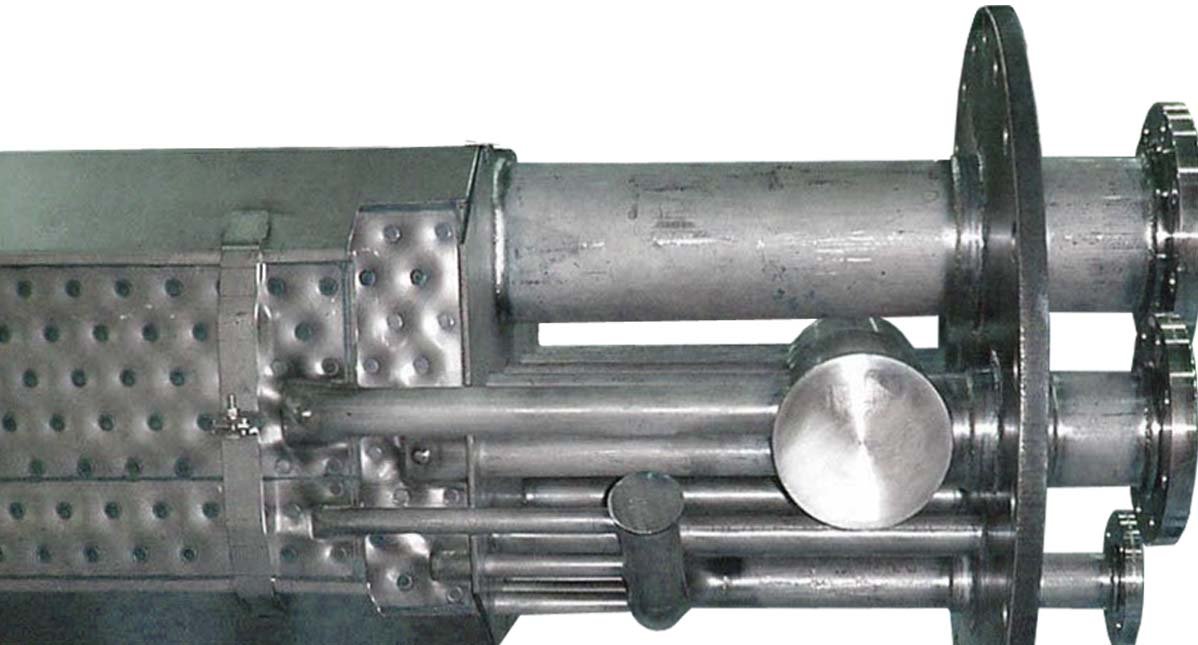

Bayonet Heaters

Bayonet heaters are an energy efficient, water saving alternative to steam sparging for heating process vessels.

Bayonet heaters are installed in the side entry of the tank. A mounting flange, which is provided, is bolted to the side of the tank for ease of insertion and removal. This allows for good natural convection circulation of the fluid being heated. These heaters are ideal for use in recirculating systems and other applications where automatically controlled temperatures are needed.

Bayonet/Suction Heater Animation

SUCTION HEATERS

The manufacturing process for suction heaters is essentially the same as bayonet heaters with the exception of a four-sided sealed shroud that encloses the plates with an opening on the far end. An outlet flange is then welded to the mounting flange that secures it to the tank. As liquid is pumped out of the tank, it is heated or cooled as it passes over the plates.Bayonet heaters and suction heaters are constructed of stainless steel and other alloys.

EASY INSTALLATION & REMOVAL

REQUIRE LITTLE TO NO MAINTENANCE

EFFICIENTLY TRANSFER HEAT

Read more about our Heat Exchangers & Applications in our literature!

SPECIFICATIONS

Bayonet/Suction Heaters require the right source of heat, temperature, moisture and flow. Heating Mediums

Many different mediums can be used in a Bayonet/Suction Heater including steam, hot oil, hot water, etc.Tank Fluids

Any viscous fluid would be a candidate for this type of heat exchanger. Some examples are: fuel oil, heavy fuel oil, crude oil, heavy crude oil, asphalt, maple syrup & molasses.Material

Bayonet/Suction Heaters are made of stainless steel and other alloys.Applications

Our Bayonet/Suction Heaters are used in many applications:Chemical IndustryOil & Gas IndustryFood & Beverage Industry

Share On

Contact us to learn about different product variations, materials & heat transfer mediums!