Contact us to learn more about our products!

Immersion Products

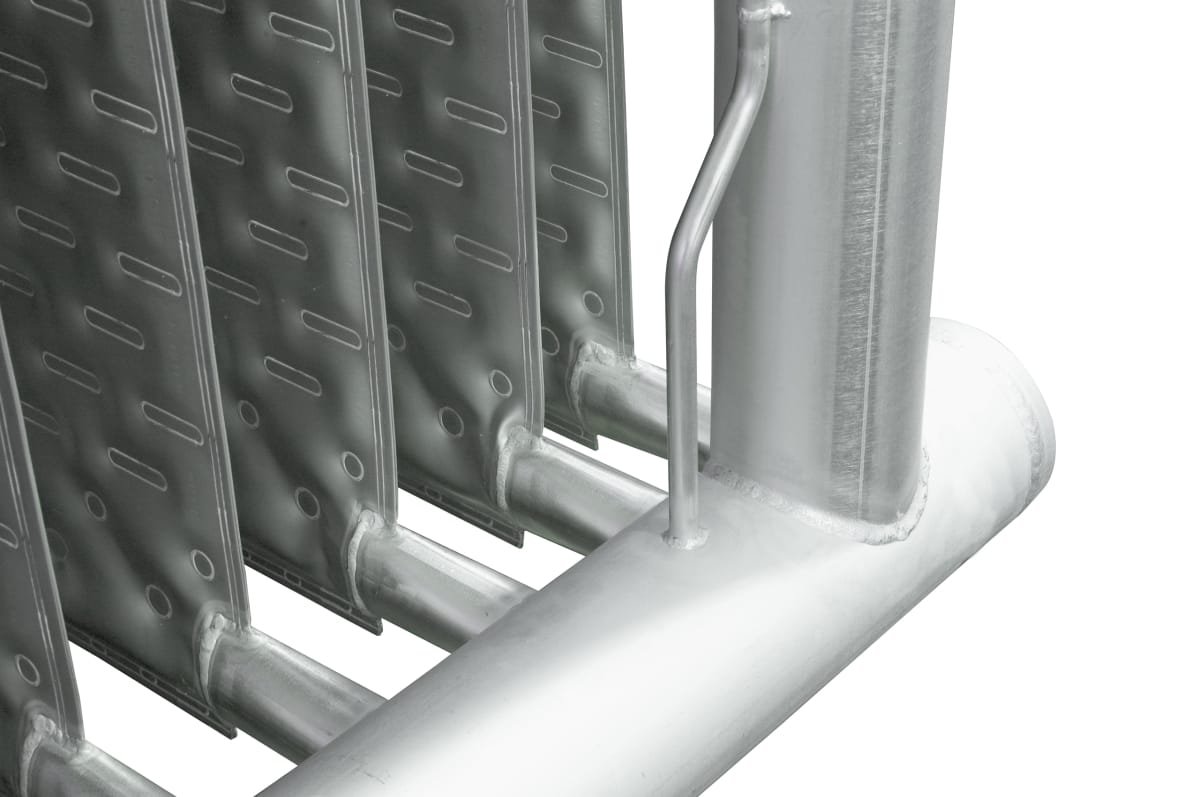

With Omega’s Immersion Plates it is easy to directly heat or cool a liquid. The sturdy design ensures that the product is easy to clean and maintain. Whether it is for clean water or heavily contaminated liquids, Laser Plates can maintain performance. Immersion Plates were initially used to heat or cool highly contaminated liquids. Several industries use this efficient method of direct heating and cooling.How does an Immersion Plate work?

Immersion products are individual plates or a bank of several Laser Plates that are immersed in a container with liquid. The medium in the plates heats or cools the liquid in the container, depending on your needs. This can be done in a continuous or a batch process.Air agitation

In order to obtain a turbulent flow on the wall of the plate, air agitation is suggested and used in some cases. This ensures a higher rate of heat transfer. An air pump blows air through a perforated pipe system, creating a whirlpool effect. This is especially recommended for cooling in Ice Bank applications.Advantages

Heating and cooling a variety of liquids, even liquids with high viscositiesEasy to maintain due to sufficient plate spacingCompact design that can be used for multiple applicationsCan also be used with highly variable volume flows

Immersion Plate Animation

COOLING/HEATING LIQUIDS WITH HIGH VISCOSITY

EASY TO MAINTAIN

HIGH HEAT TRANSFER CAPABILITIES

Read more about our Heat Exchangers & Applications in our literature!

SPECIFICATIONS

You determine the dimensions and the capacity of the Immersion Plates together with one of our engineers. This depends on the medium you want to use to heat or cool, whether it is a batch or a continuous process, the available space and the desired capacity.Capacity

We can carry out our Immersion Products, depending on the available dimensions, up to capacities of 10,000 BTU/Hr per unit. This allows you to cool your liquid to 33°F without the risk of damage by freezing ice.Cooling medium

Almost all cooling mediums can be used with Immersion Plates, such as R717, CO2, Propylene Glycol, Ethylene Glycol, R22, R134A and R404A.Material

Immersion Plates are made of stainless steel, such as 304, 316, SMO-254 and Duplex 2205.Applications

Our Immersion Plates have often been used to cool highly contaminated liquids. Immersion Plates are now also used for other applications. If you are interested and want to know whether an Immersion Plate can also be used for your industry, please contact one of our engineers.Poultry industryBakery industryDairy industryMeat processing industryFishing industryFood industry

You can also choose a combination of Ice Bank and Immersion Plates. During operation hours, the plates can function as a water chiller, while at night, when there is no consumption, the cooler builds up ice.Share On

Contact us to learn about different product variations, materials & heat transfer mediums!